An air-cooled water chiller is a cooling system that uses air as the medium to dissipate heat from the refrigeration cycle. Designed for industrial, commercial, and residential applications, these chillers are versatile and require less maintenance compared to water-cooled systems. They are widely used in industries requiring efficient temperature control, such as HVAC, food processing, pharmaceuticals, and manufacturing.

An air-cooled water chiller is a cooling system that uses air as the medium to dissipate heat from the refrigeration cycle. Designed for industrial, commercial, and residential applications, these chillers are versatile and require less maintenance compared to water-cooled systems. They are widely used in industries requiring efficient temperature control, such as HVAC, food processing, pharmaceuticals, and manufacturing.

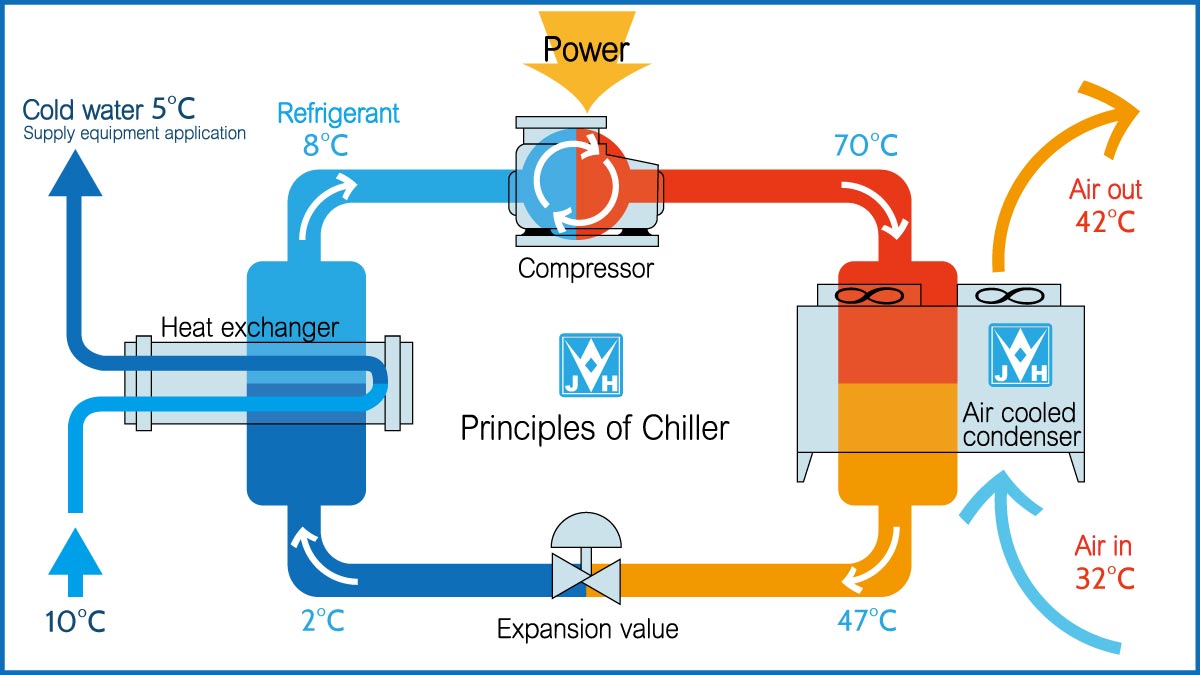

Refrigeration Cycle:

Provides efficient cooling for commercial and industrial buildings.

Used for cooling processes like fermentation, storage, and production.

Maintains precise temperatures for chemical reactions and storage.

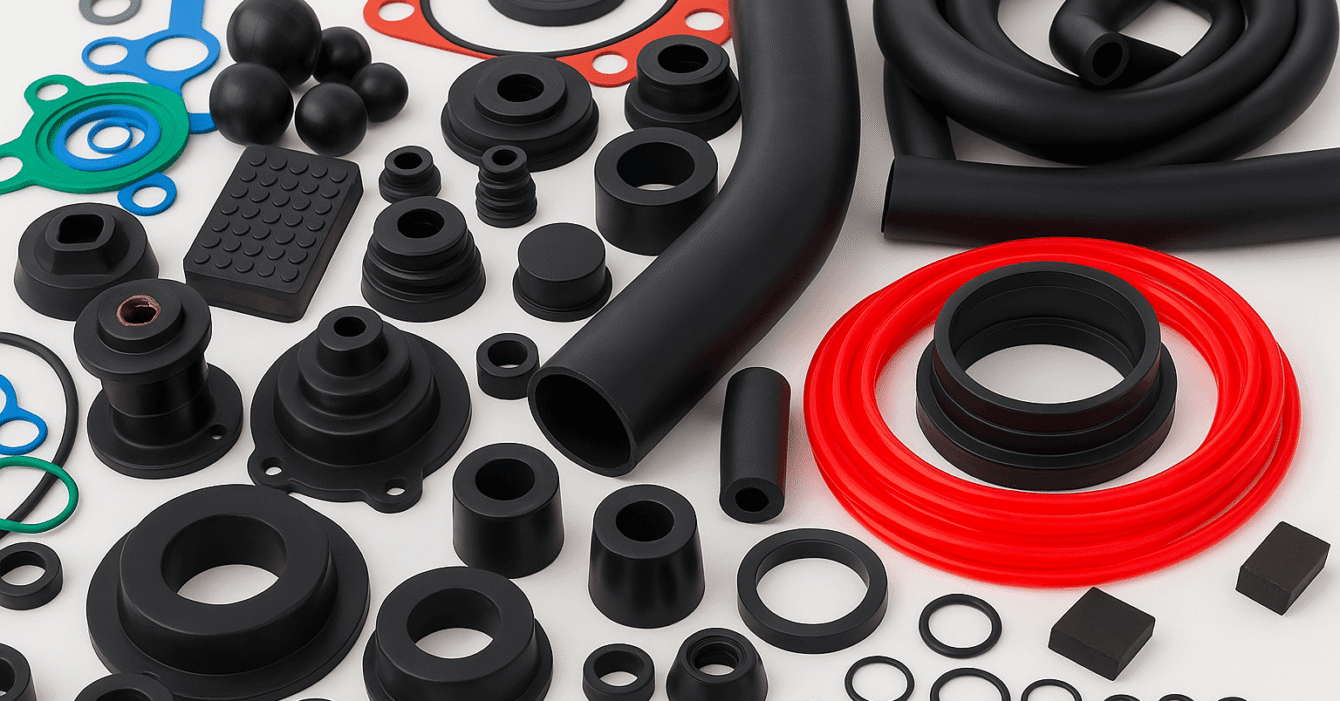

Cools molds, machines, and products during manufacturing.

Control temperature during cutting, welding, and other operations.

Ensures consistent ink drying and maintains machine temperature.

Provides cooling for MRI machines, lasers, and other equipment.

SPH SERIES (Side Blowing)

| Model | SPH10 | SPH20 | SPH30 | SPH40 | SPH60 | SPH80 | ||

|---|---|---|---|---|---|---|---|---|

| Cooling Capacity | kW/hr | 1.4 | 2.6 | 3.5 | 5.3 | 7 | 10 | |

| kcal/hr | 1200 | 2230 | 3010 | 4560 | 6020 | 8600 | ||

| Compressor Power | HP | 0.5 | 1 | 1.5 | 2 | 3 | 4 | |

| Water Pump | kW | 0.28 | 0.37 | 0.5 | 0.5 | 0.5 | 0.83 | |

| HP | 0.37 | 0.5 | 0.7 | 0.7 | 0.7 | 1.11 | ||

| Power Supply | 240V, 50Hz, 1-Phase | 415V, 50Hz, 3-PHASE | ||||||

| Refrigerant | R40C | |||||||

| Cold Water Flow | Rate | l/min | 7 | 20 | 25 | 25 | 33 | 65 |

| Head | Meter | 12 | 15 | 20 | 20 | 20 | 20 | |

| Condensing Fan Size | Inch | 10” | 14” | 14” | 16” | 16” | 20” | |

| Pipe Size (In/Outlet) | Inch | 1/2” X 1/2” | 1/2” X 1/2” | 1” X 1” | 1” X 1” | 1” X 1” | 1” X 1” | |

| Dimension | Length | mm | 505 | 720 | 750 | 750 | 875 | 1150 |

| Width | mm | 400 | 380 | 570 | 570 | 610 | 680 | |

| Height | mm | 470 | 915 | 1075 | 1075 | 1160 | 1075 | |

| S/Steel Water Tank Volume | Liter | 5 | 17 | 20 | 22 | 30 | 32 | |

| Gross Weight | kg | 50 | 60 | 95 | 120 | 140 | 170 | |

SP SERIES (Upward Blowing)

| Model | SP30 | SP40 | SP60 | SP80 | SP100 | SP200 | SP300 | SP420 | SP500 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Capacity | kW/hr | 3.5 | 5.3 | 7 | 10 | 13 | 19 | 27 | 31 | 39 | |

| kcal/hr | 3010 | 4560 | 6020 | 8600 | 11180 | 16340 | 23220 | 26660 | 33540 | ||

| Compressor Power | HP | 1.5 | 2 | 3 | 4 | 5 | 7 | 10 | 12 | 15 | |

| Water Pump | kW | 0.5 | 0.5 | 0.5 | 0.83 | 0.83 | 1.11 | 1.11 | 1.6 | 2.5 | |

| HP | 0.7 | 0.7 | 0.7 | 1.11 | 1.11 | 1.5 | 1.5 | 2.15 | 3 | ||

| Power Supply | 415V, 50Hz, 3-PHASE | ||||||||||

| Refrigerant | R407C | ||||||||||

| Cold Water Flow | Rate | l/min | 25 | 25 | 33 | 65 | 65 | 100 | 110 | 130 | 180 |

| Head | Meter | 20 | 20 | 20 | 20 | 20 | 25 | 25 | 25 | 30 | |

| Condensing Fan Size | Inch | 14” | 16” | 16” | 20” | 20” | 18” X 2 | 20” X 2 | 20” X 2 | 22” X 2 | |

| Pipe Size (In/Outlet) | Inch | 1” X 1” | 1” X 1” | 1” X 1” | 1” X 1” | 1” X 1” | 1 1/4” X 1 1/4” | 1 1/4” X 1 1/4” | 1 1/4” X 1 1/4” | 1 1/4” X 1 1/4” | |

| Dimension | Length | mm | 750 | 750 | 875 | 1150 | 1150 | 1050 | 1050 | 1050 | 1050 |

| Width | mm | 570 | 570 | 610 | 680 | 680 | 900 | 900 | 900 | 1030 | |

| Height | mm | 1175 | 1175 | 1300 | 1300 | 1300 | 1500 | 1500 | 1500 | 1550 | |

| S/Steel Water Tank Volume | Liter | 20 | 22 | 30 | 32 | 32 | 125 | 125 | 125 | 180 | |

| Gross Weight | kg | 95 | 120 | 140 | 170 | 190 | 380 | 380 | 410 | 435 | |

SFA SERIES

| Model | SFA170 | SFA200 | SFA500 | SFA600 | SFA840 | SFA1000 | ||

|---|---|---|---|---|---|---|---|---|

| Cooling Capacity | kW/hr | 20 | 26 | 31 | 54 | 62 | 78 | |

| kcal/hr | 17200 | 22360 | 34400 | 46400 | 53400 | 67200 | ||

| Compressor Power | HP | 4HP X 2 | 5HP X 2 | 10HP + 5HP | 10HP X 2 | 12HP X 2 | 15HP X 2 | |

| Water Pump | kW | 1.11 | 1.6 | 2.5 | 3 | 3 | 4 | |

| HP | 1.5 | 2.13 | 3.3 | 4 | 4 | 5.4 | ||

| Power Supply | 415V, 50Hz, 3-PHASE | |||||||

| Refrigerant | R407C | |||||||

| Cold Water Flow | Rate | l/min | 100 | 110 | 180 | 250 | 300 | 360 |

| Head | Meter | 25 | 30 | 30 | 30 | 30 | 30 | |

| Condensing Fan Size | Inch | 20” X 2 | 20” X 2 | 20” X 3 | 20” X 4 | 20” X 4 | 22” X 4 | |

| Pipe Size (In/Outlet) | Inch | 1 1/4” X 1 1/4” | 1 1/4” X 1 1/4” | 1 1/2” X 1 1/2” | 1 1/2” X 1 1/2” | 2” X 2” | 2” X 2” | |

| Dimension | Length | mm | 1000 | 1650 | 2300 | 1905 | 1905 | 2260 |

| Width | mm | 900 | 900 | 900 | 1560 | 1560 | 1800 | |

| Height | mm | 1500 | 1500 | 1450 | 1850 | 1850 | 1850 | |

| S/Steel Water Tank Volume | Liter | 130 | 130 | 140 | 320 | 320 | 400 | |

| Gross Weight | kg | 360 | 380 | 450 | 815 | 850 | 950 | |

SMA SERIES

| Model | SMA315 | SMA330 | SMA336 | SMA345 | SMA440 | SMA460 | SMA575 | SMA690 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Capacity | kW/hr | 39 | 81 | 93 | 117 | 108 | 156 | 195 | 234 | |

| kcal/hr | 33540 | 69600 | 80000 | 100600 | 92900 | 134200 | 167700 | 201200 | ||

| Compressor Power | HP | 5HP X 3 | 10HP X 3 | 12HP X 3 | 15HP X 3 | 10HP X 4 | 15HP X 4 | 15HP X 5 | 15HP X 6 | |

| Water Pump | kW | 1.6 | 2.2 | 3 | 3 | 3 | 4 | 5.5 | 5.5 | |

| HP | 3 | 3 | 4 | 4 | 4 | 5.5 | 7.5 | 7.5 | ||

| Power Supply | 415V, 50Hz, 3-PHASE | |||||||||

| Refrigerant | R407C | |||||||||

| Cold Water Flow | Rate | l/min | 180 | 300 | 400 | 500 | 500 | 700 | 800 | 1000 |

| Head | Meter | 20 | 25 | 25 | 20 | 20 | 20 | 25 | 20 | |

| Condensing Fan Size | Inch | 20” X 3 | 20” X 6 | 20” X 6 | 20” X 8 | 20” X 8 | 22” X 8 | 22” X 10 | 22” X 12 | |

| Pipe Size (In/Outlet) | Inch | 1 1/2” X 1 1/2” | 1 1/2” X 1 1/2” | 2” X 2” | 2” X 2” | 2” X 2” | 2” X 2” | 2” X 2” | 2” X 2” | |

| Dimension | Length | mm | 2330 | 2360 | 2360 | 3180 | 3100 | 4100 | 5100 | 6100 |

| Width | mm | 900 | 1500 | 1500 | 1830 | 1500 | 1870 | 1870 | 1870 | |

| Height | mm | 1450 | 1600 | 1600 | 1800 | 1800 | 1800 | 1800 | 1800 | |

| S/Steel Water Tank Volume | Liter | 140 | 400 | 500 | 500 | 500 | 800 | 1000 | 1000 | |

| Gross Weight | kg | 500 | 630 | 668 | 820 | 1400 | 1900 | 2400 | 2800 | |

*Cooling Capacity rate is based on ambient air temperature of 35°C or below.

**Specification subject to change without prior notice.

Air-cooled chillers require no water supply or cooling towers, making them easier to install and maintain in areas with water scarcity.

Most models can maintain temperatures from 5°C to 30°C, depending on the application.

The air-cooled condenser should be cleaned every 3-6 months, or more frequently in dusty environments.

Yes, they are designed for outdoor use with weather-resistant components.

With proper maintenance, the lifespan is typically 15-20 years.

Yes, most air-cooled chillers are designed to operate efficiently in ambient temperatures up to 45°C, with some high-ambient models capable of handling more.

The sizing depends on the cooling load, process requirements, and environmental factors. A detailed load calculation by an expert is recommended.

Common refrigerants include R134a, R410A, and R407C, with options for environmentally friendly alternatives.