- Cooling Moulds: injection moulding, blow moulding and extrusion

- CNC Industries: CNC maching center, CNC electrical discharge machine, CNC grinder, CNC Lather

- Laser Cutting, DI Water Application

- Electroplating

- Air pressure spot welder

- Food Processing

- machinery using hydraulic oil, lubricating oil or other processing oil

SMW Multi-Compressor Series

Features

- Use two or more compressors to perform the cooling function

- Can maintain the Temperature Accuracy within ± 1˚C (particularly suitable for industries in which precise temperature is needed)

- Can reduce the Temperature Variation from 3-5˚C (regular chiller) 1˚C

- Fully utilize the compressors as they will take turns to operate under the control of our specially programmed PCR (Programmable Control Relay)

- Can lower the start-up current usage and reduce the chance of current surge

Specification

| Model | SMW315 | SMW330 | SMW336 | SMW440 | SMW345 | SMW448 | SMW460 | SMW575 | SMW690 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Capacity | Kcal/hr

KW |

38700

45 |

82560

96 |

94200

110 |

110080

128 |

129000

150 |

125600

146 |

172000

200 |

245000

250 |

258000

300 |

| Compressor | HP | 5 x 3 | 10 x 3 | 12 x 3 | 10 x 4 | 15 x 3 | 12 x 4 | 15 x 4 | 15 x 5 | 15 x 6 |

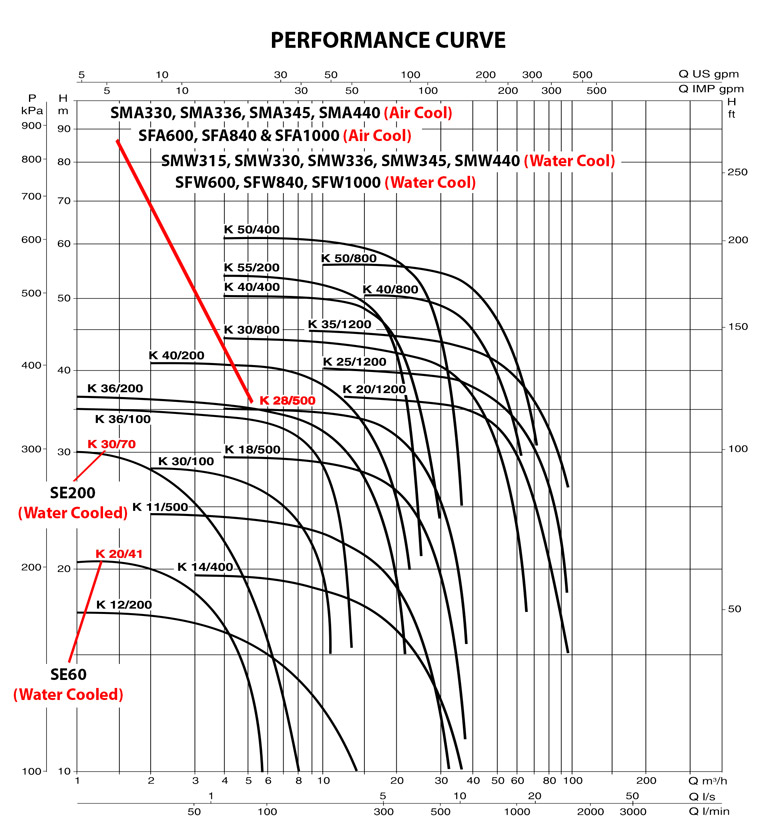

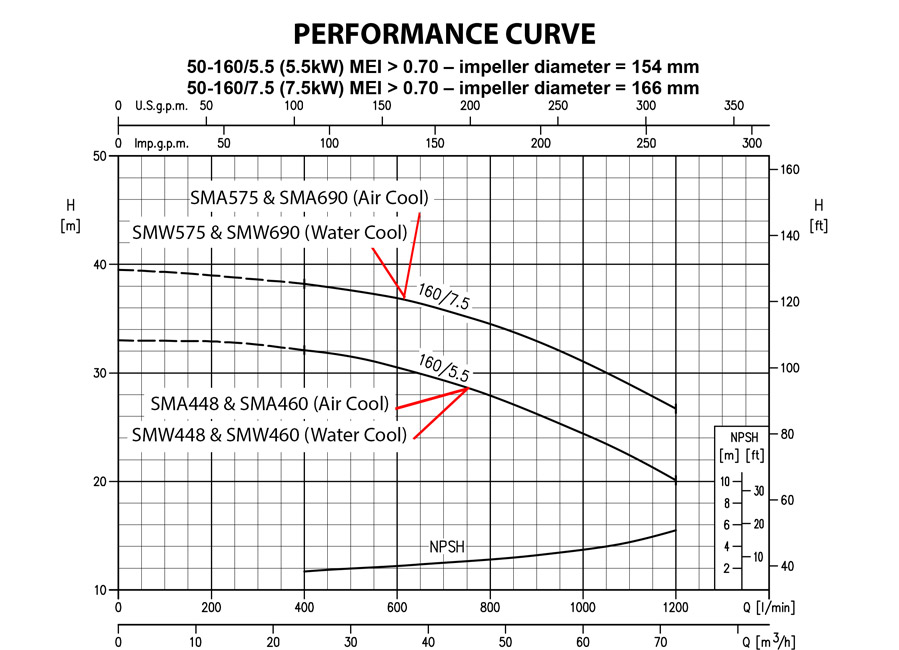

| Water Pump | HP | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 | 10 | 10 |

| Water Flow Rate | L/min@Bar | 350@3 | 350@3 | 350@3 | 400@3.5 | 450@3.3 | 500@3.2 | 600@3 | 750@3.4 | 900@3.2 |

| S/S Water Tank Volume | Litre | 180 | 330 | 600 | 800 | 800 | 1000 | 1000 | 1200 | 1400 |

| Condenser (inlet / outlet) | Inch | 2 x 2 | 2 x 2 | 2 1/2 x 2 1/2 | 3 x 3 | 3 x 3 | 3 x 3 | 3 x 3 | 3 x 3 | 3 x 3 |

| Dimension | Length mm

Width mm Height mm |

1580

900 1500 |

2430

1520 1750 |

2415

1350 1800 |

3100

1800 2000 |

2050

1300 1980 |

3500

1560 2000 |

4000

1800 2000 |

2440

1300 1800 |

6000

1800 2000 |

| Gross Weight (Dry) | KG | 330 | 630 | 670 | 820 | 815 | 1700 | 1900 | 2400 | 2800 |